SITE SPECIFIC STAMPED STRUCTURAL ENGINEERING INCLUDED WITH ALL PREMIUM MODELS

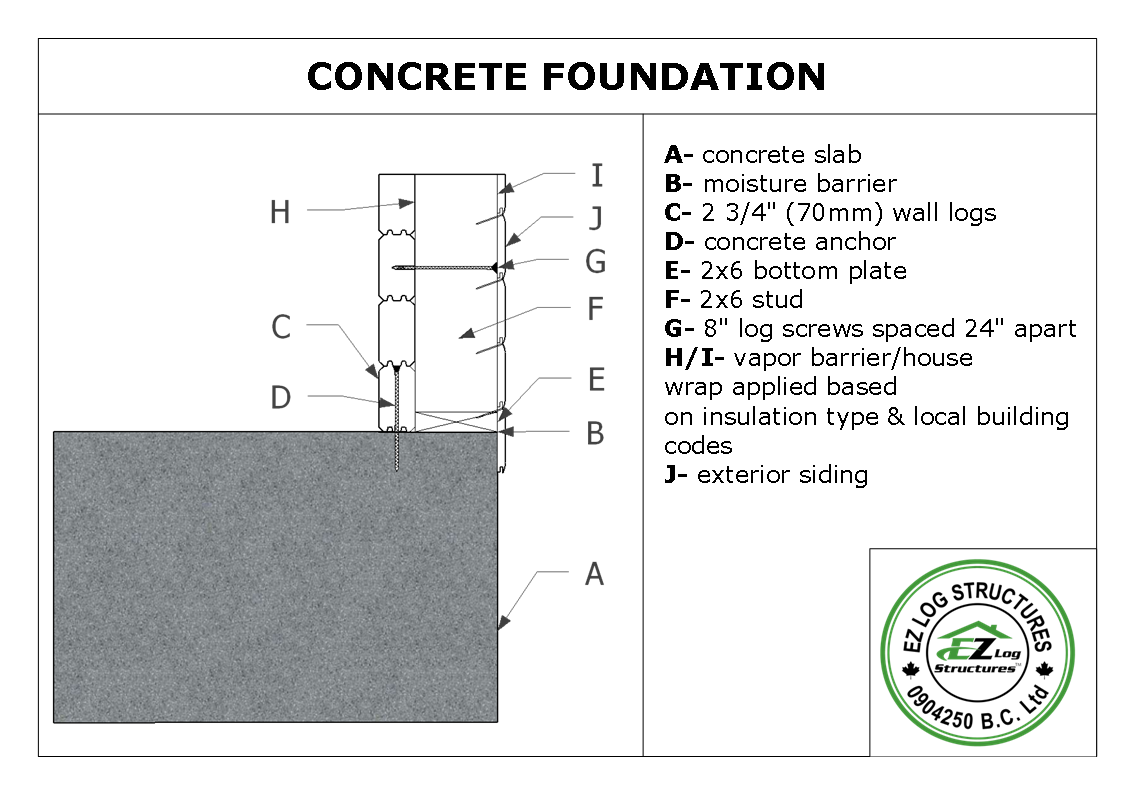

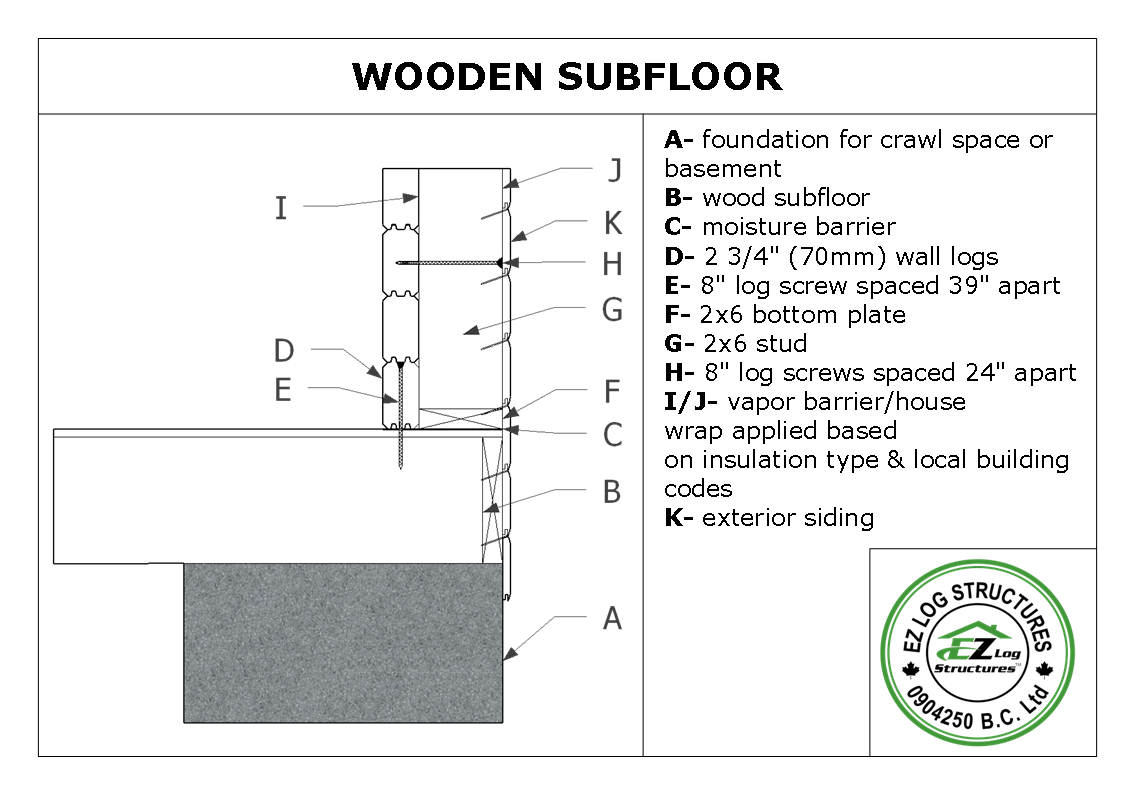

EZ Log Structures do not require skilled tradespeople for assembly, just some basic construction knowledge is required. Each package is numbered in sequence and the precut components stack by number, no cutting. Foundation sizes are provided so you can prepare your foundation of choice in advance. The kit can be assembled on a concrete slab, crawl space, post & beam or a basement with a wood subfloor the same as conventional construction. When the kit arrives you are ready to assemble.

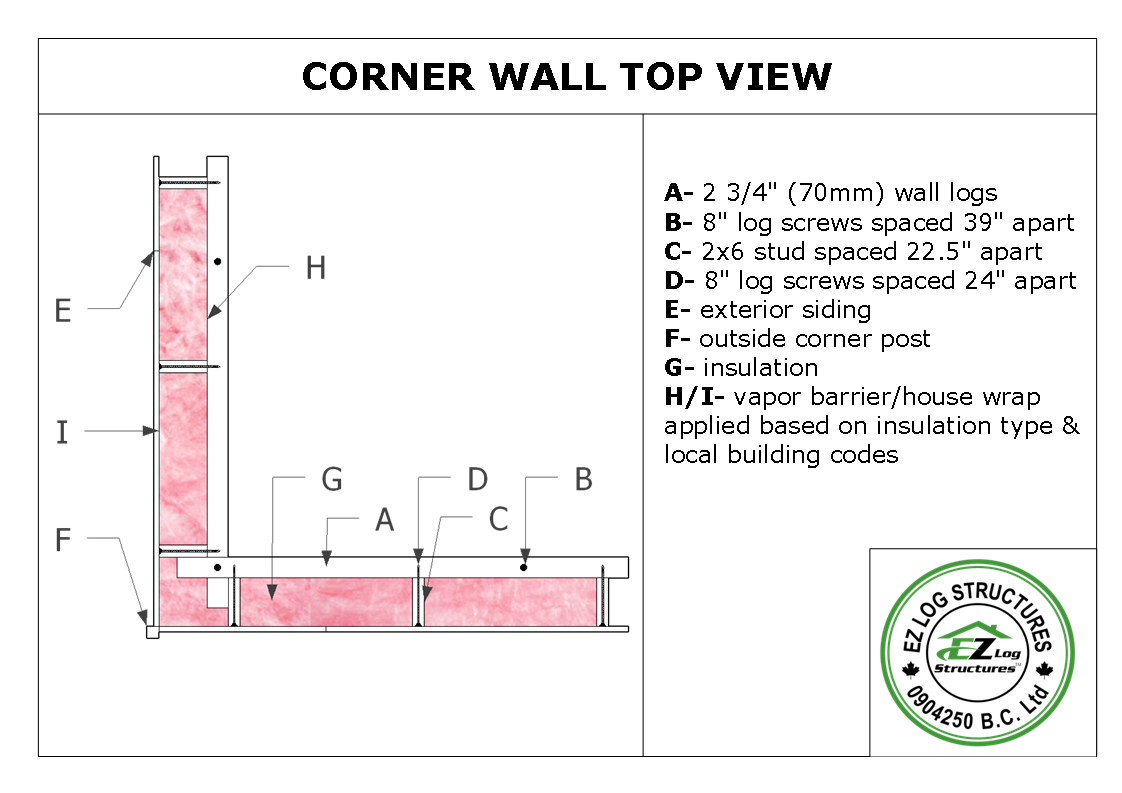

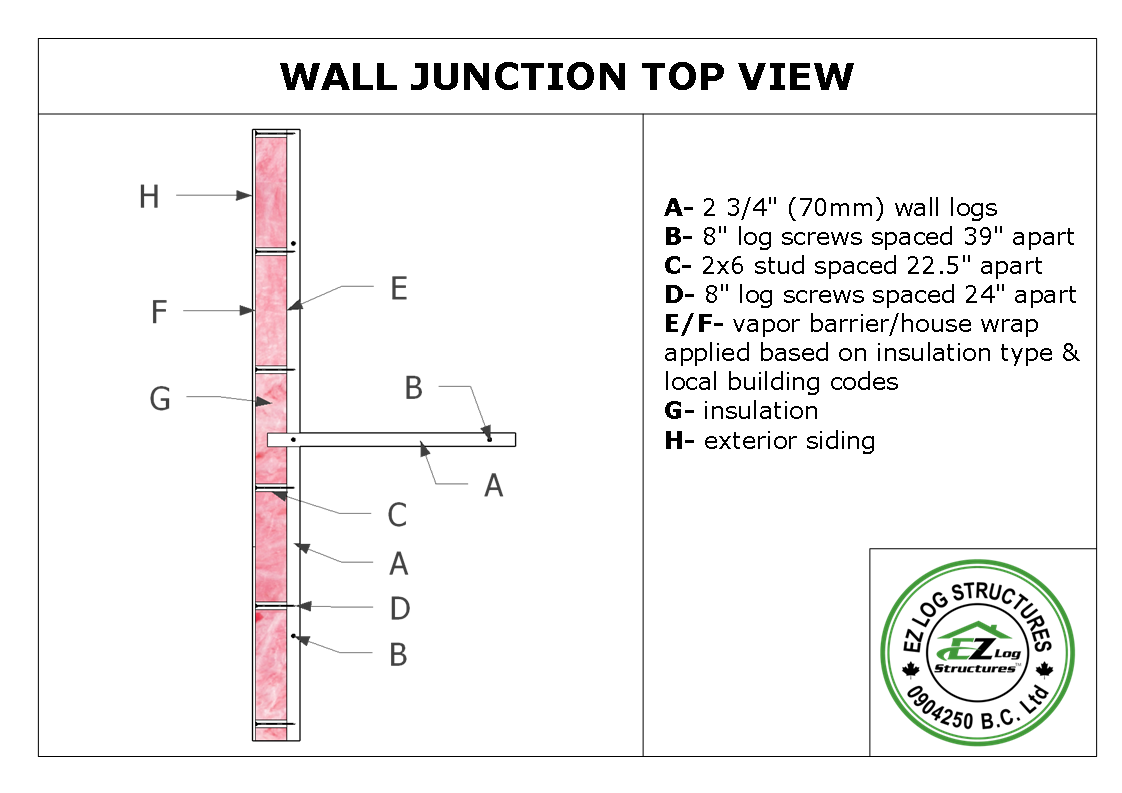

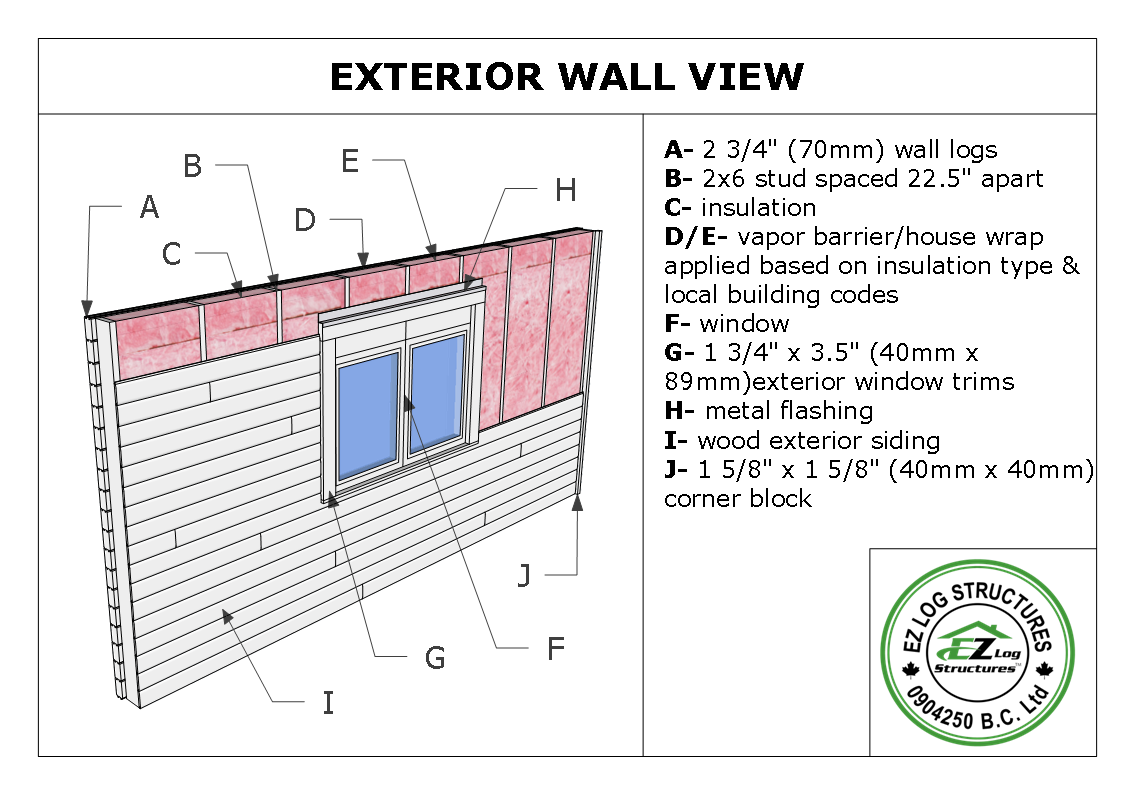

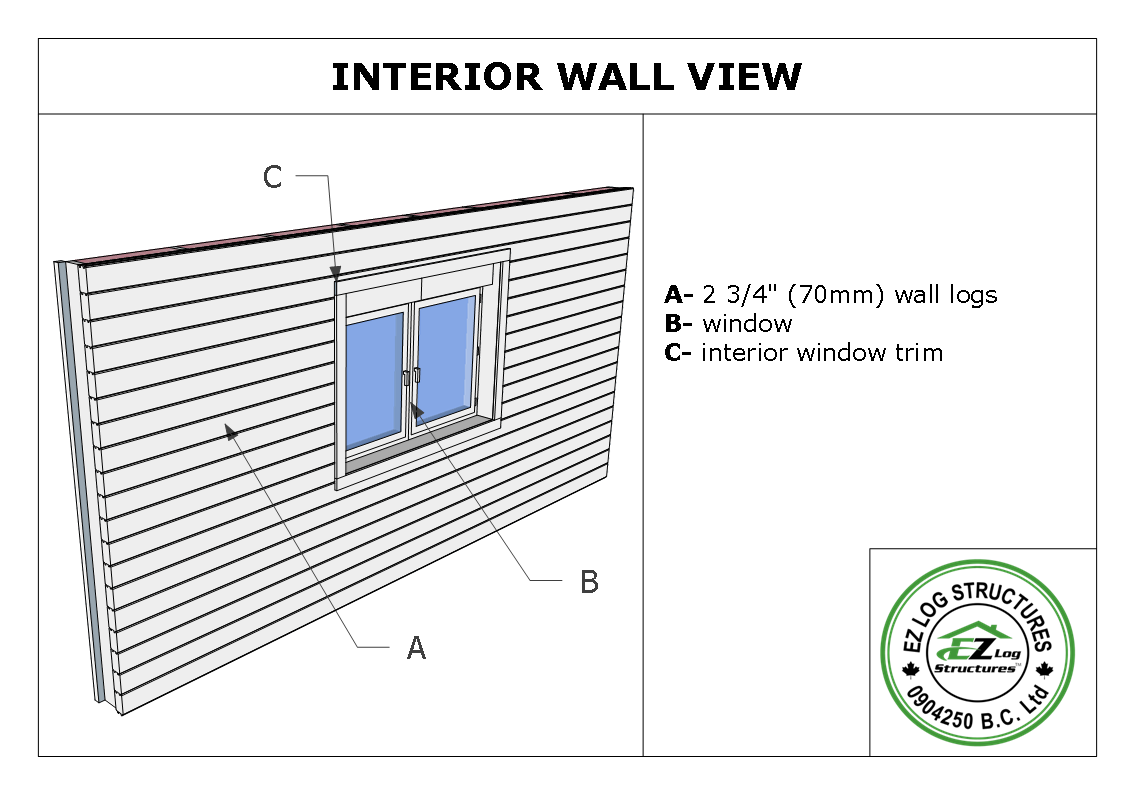

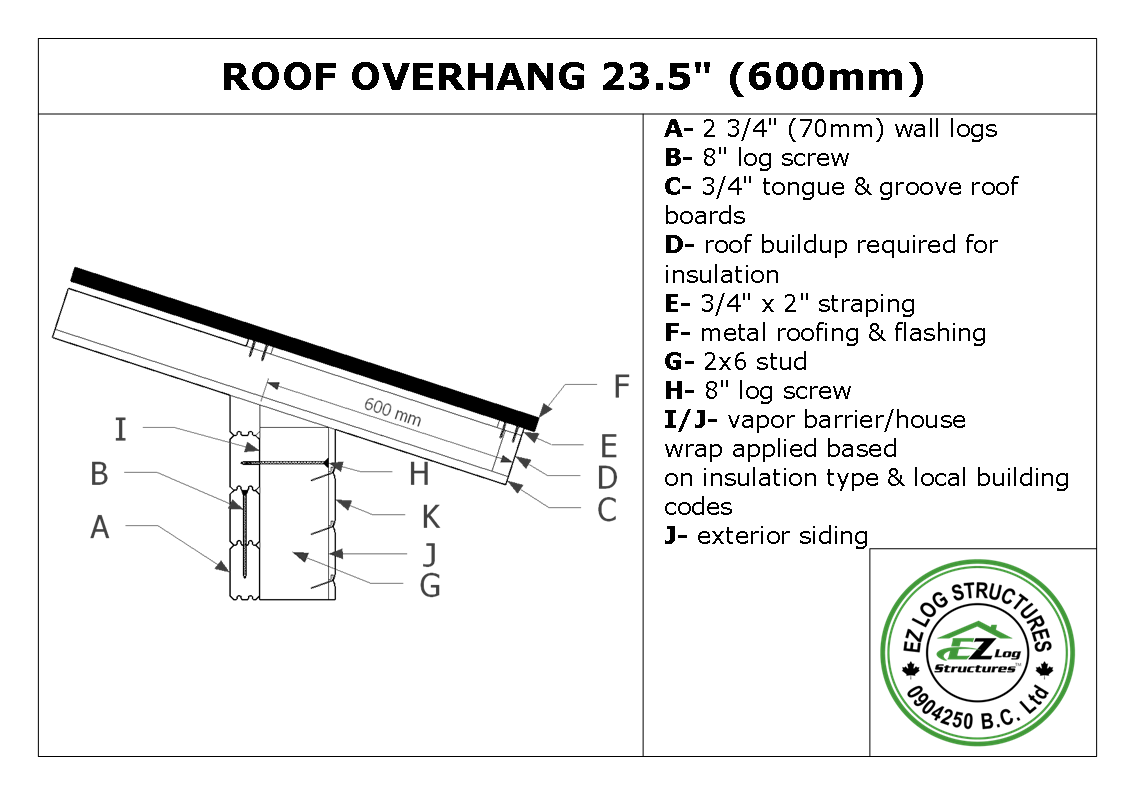

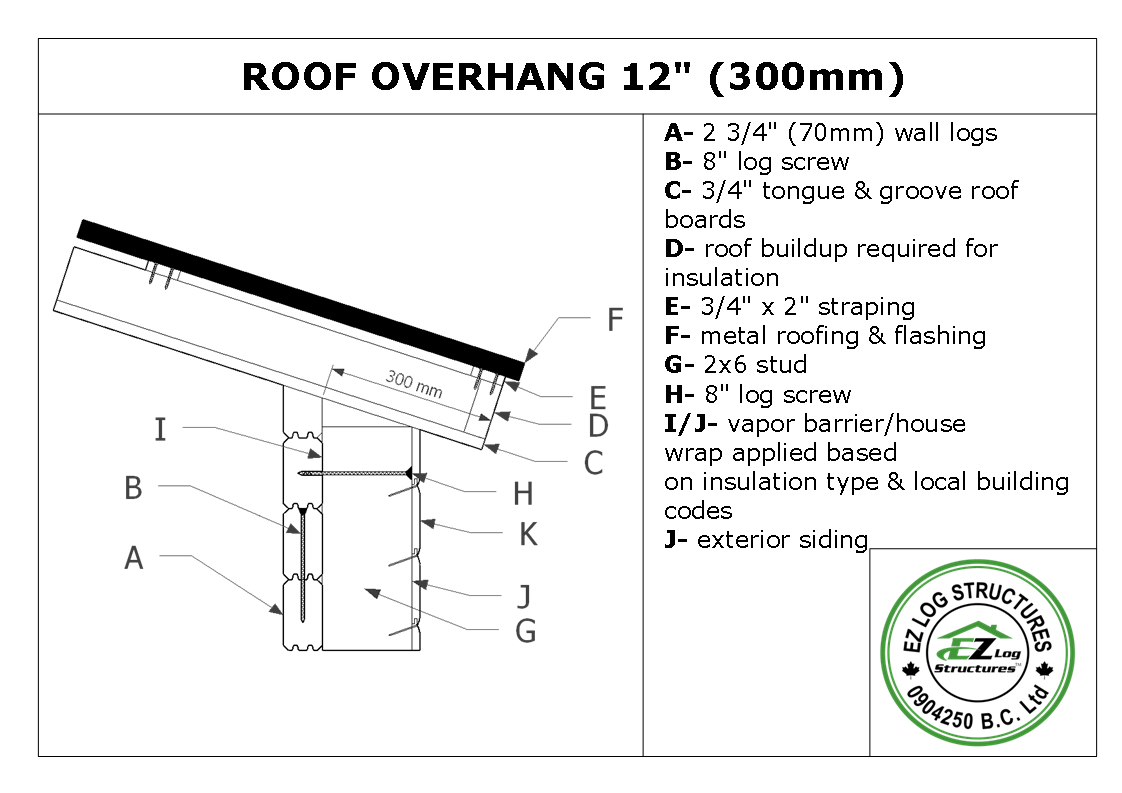

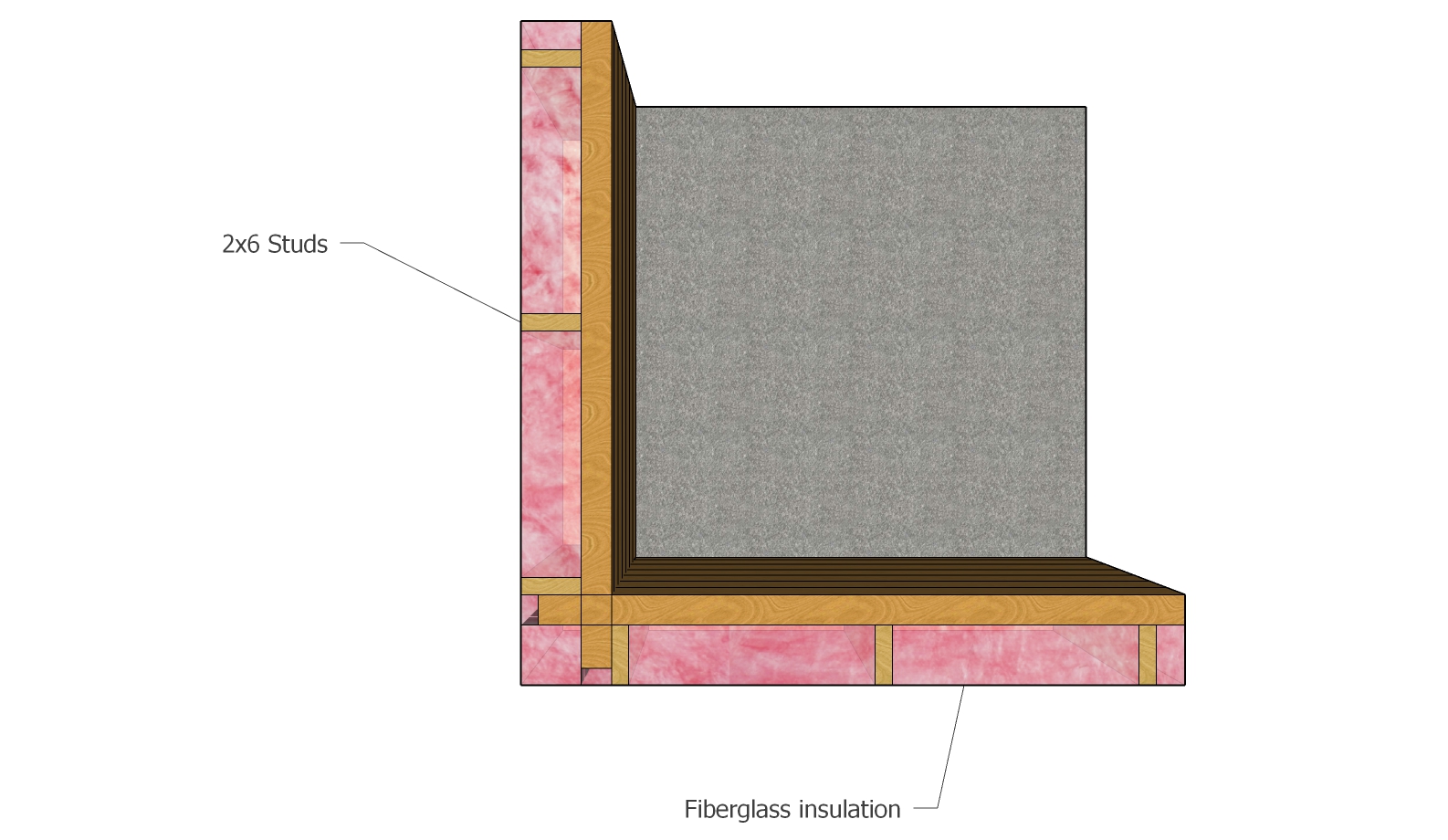

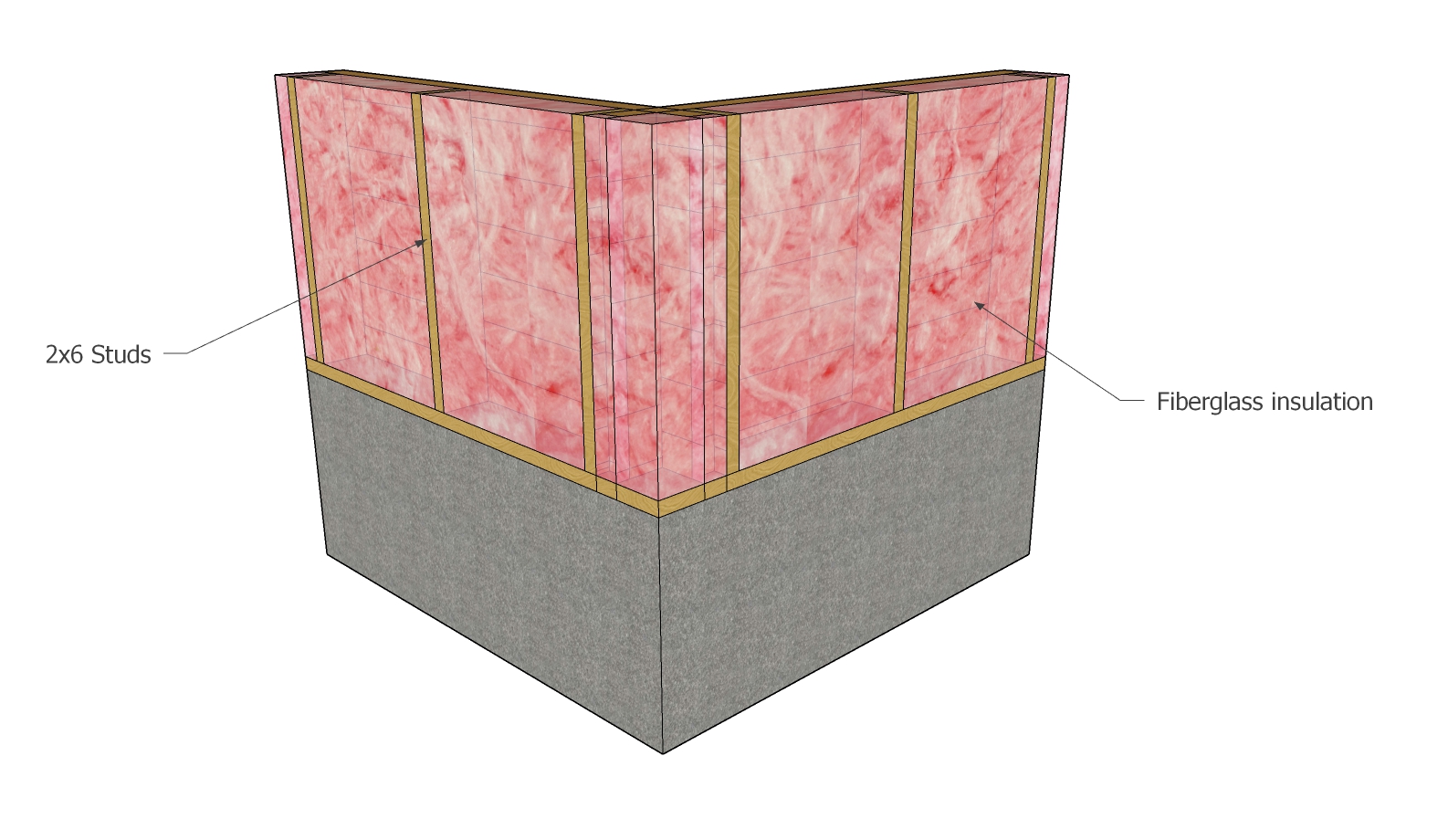

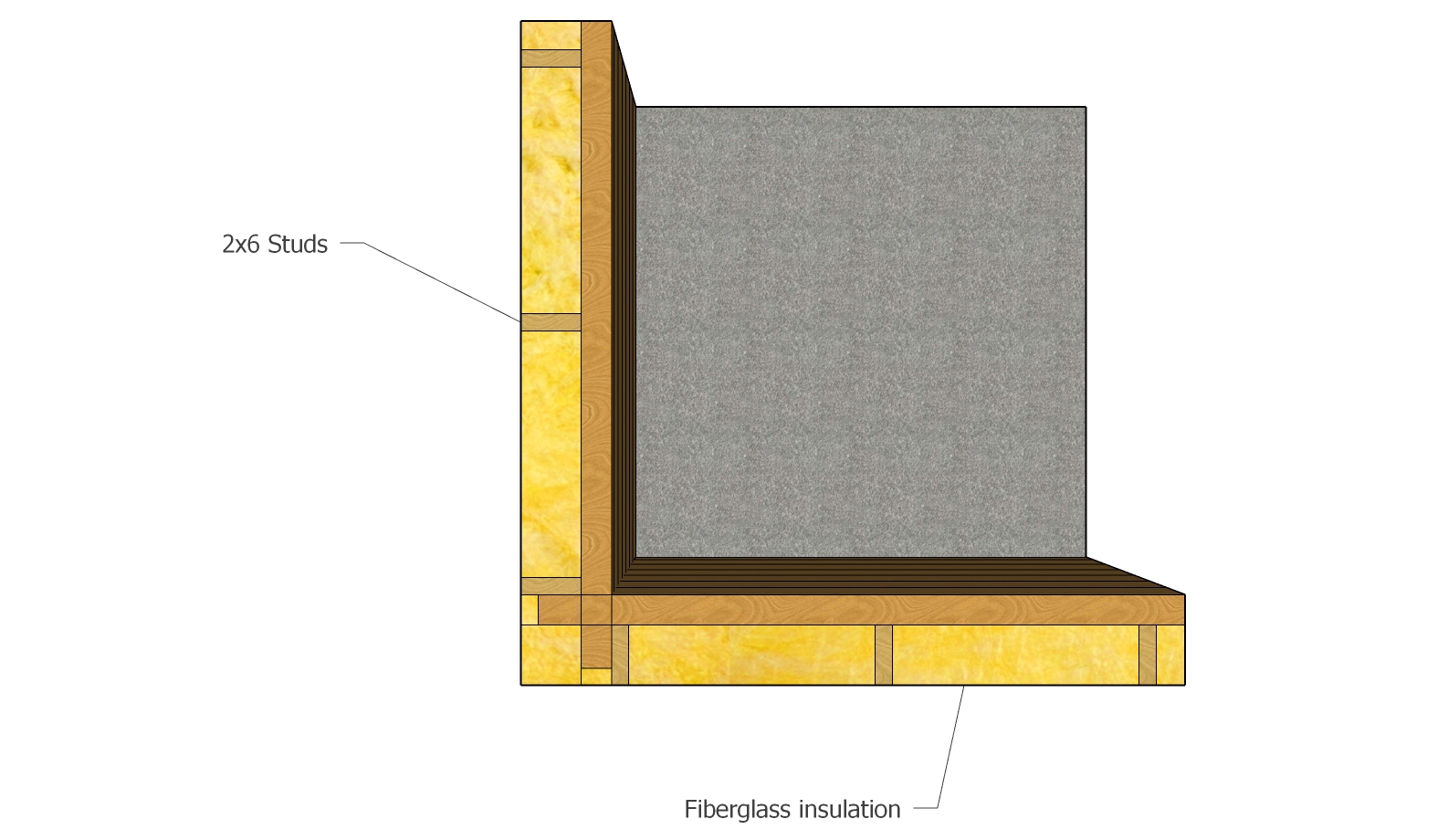

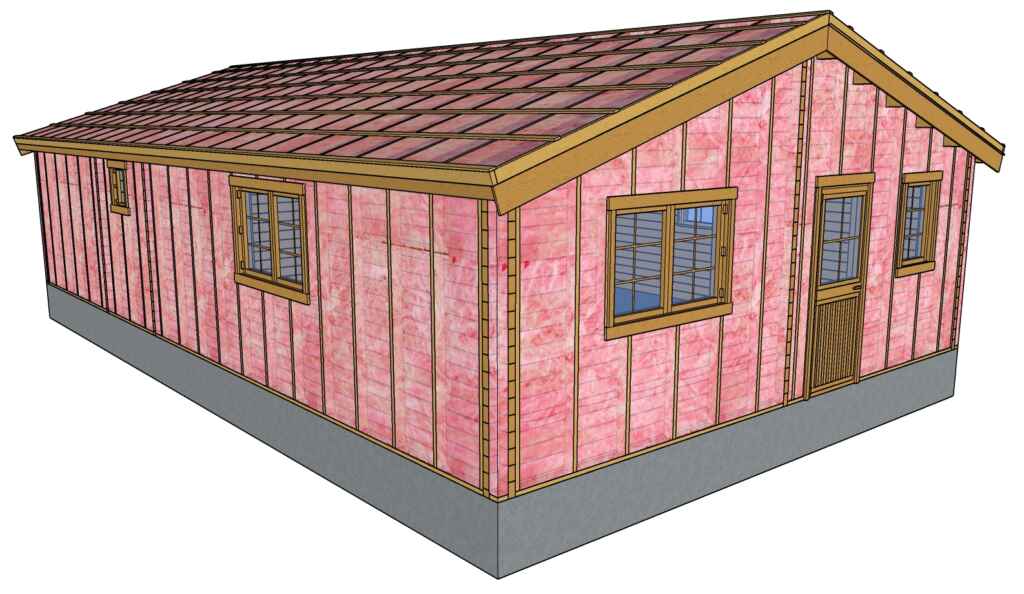

Once the kit has been assembled; kitchen cabinets, plumbing, light fixtures, interior electrical, flooring and the finishing of the interior walls can begin immediately without delays as there is no drywall/plaster boards. The 2×6 studs are applied to the exterior, wiring & insulation is installed and the exterior finish is applied. We offer 2 types of wood siding but the exterior can be finished using vinyl, hardboard, cement board siding, stucco or even brick. The result is a home that can be built in a rural or urban environment. The exterior looks like a conventional home but the interior is all natural wood ready to paint or stain.

NOTE: In some zones, insulating walls may not be required when the building is for seasonal use or the local building codes do not require insulating. In these cases it is still advised to insulate the roof and the floor when using crawl spaces.

FEATURES & BENFITS

Premium models meet structural requirements for building codes across North America

No skilled labor required, do it yourself or hire a contractor for assembly

Quicker assembly time to achieve the dry in stage

Less subtrades required

Environmentally friendly, no plastics, composites or drywall

Virtually no waste

Stronger than conventional construction

No plywood required for the walls

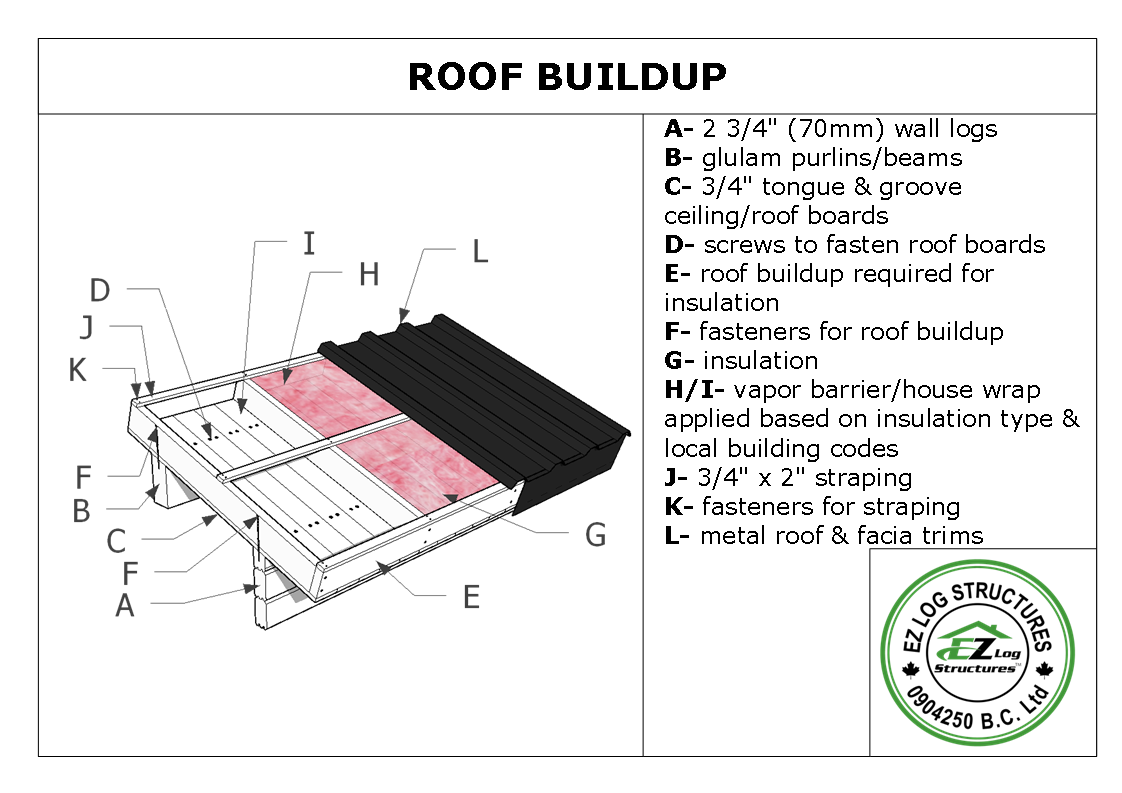

No plywood on roofs required when using metal roofing

QUICK VIEW ASSEMBLY SEQUENCE

INSULATING WALLS – SUPERIOR ENERGY EFFICIENCY

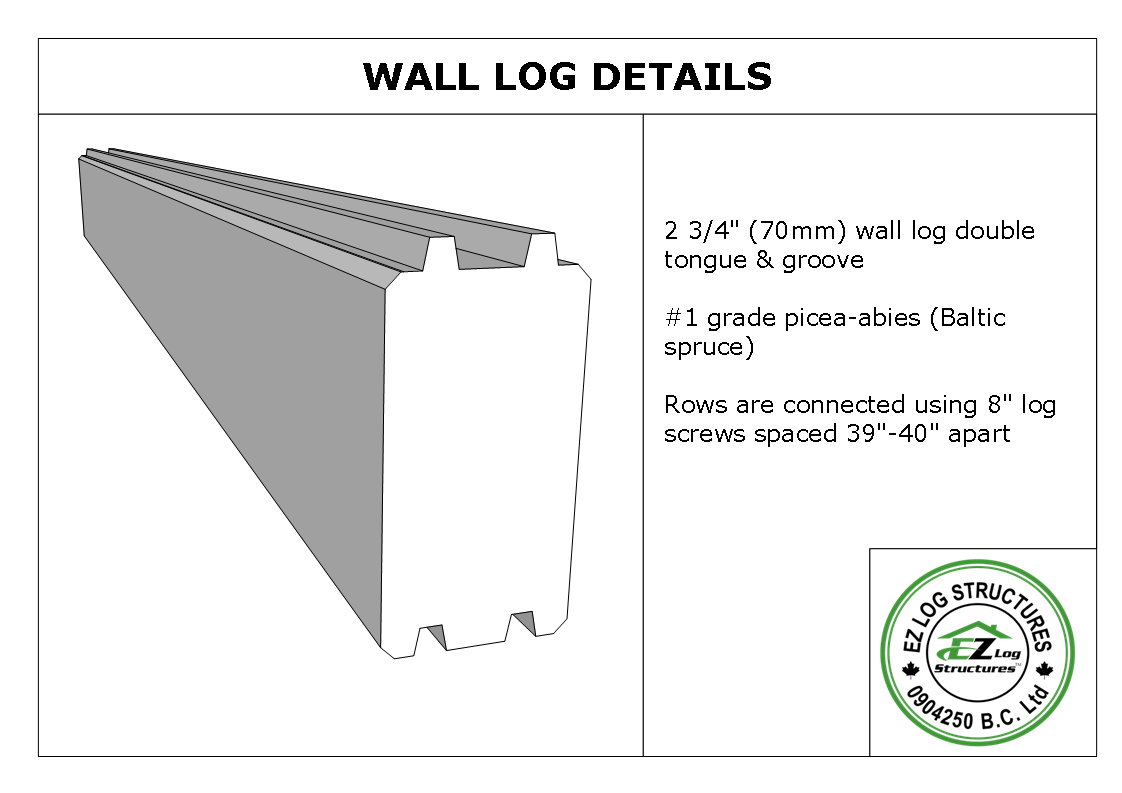

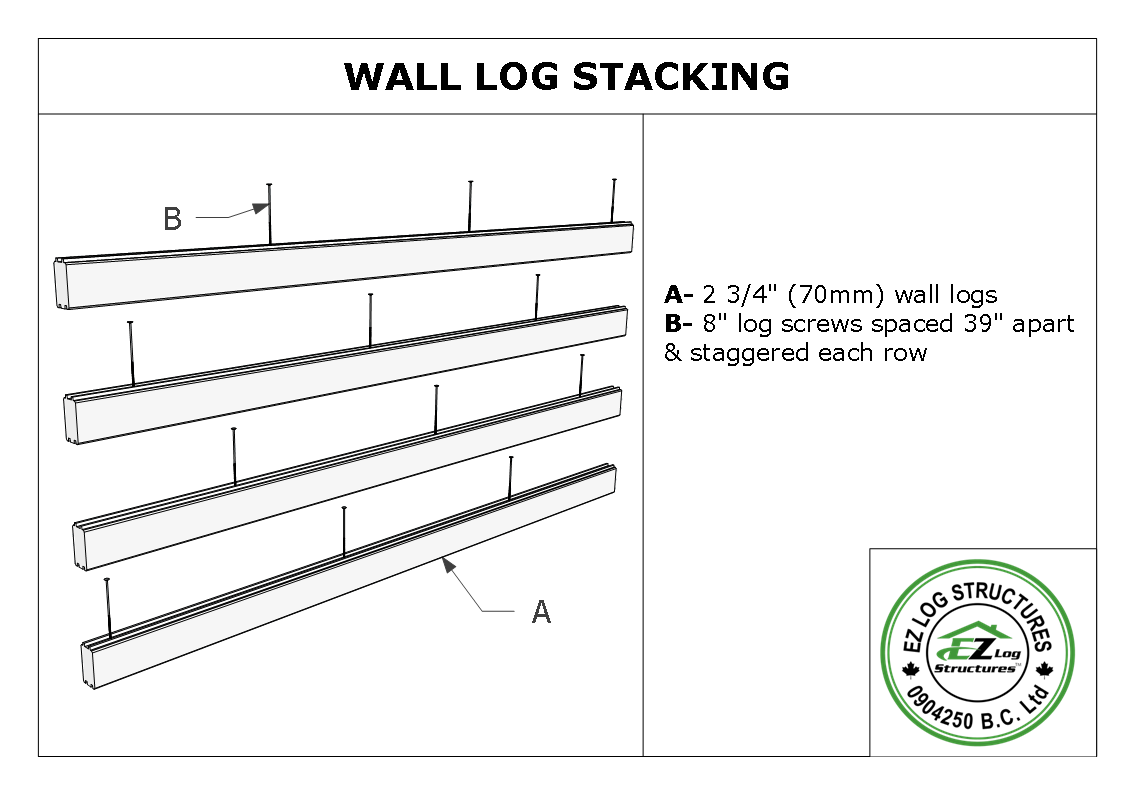

Insulating the exterior is the most efficient method. The main structure is protected from the elements keeping the wood preserved indefinitely. The main building has 2-3/4″ thick solid wood walls that provide an R-value of 4.4. This solid wood wall has virtually no heat or cold transfer, increasing the overall thermal and comfort benefits. Wall R-value is gained from applying studs, insulation and exterior siding

(vapor barrier & house wrap may be required based on local building codes)

(WALL LOG) R 4.4 + (INSULATION) R 20 = R 24.4

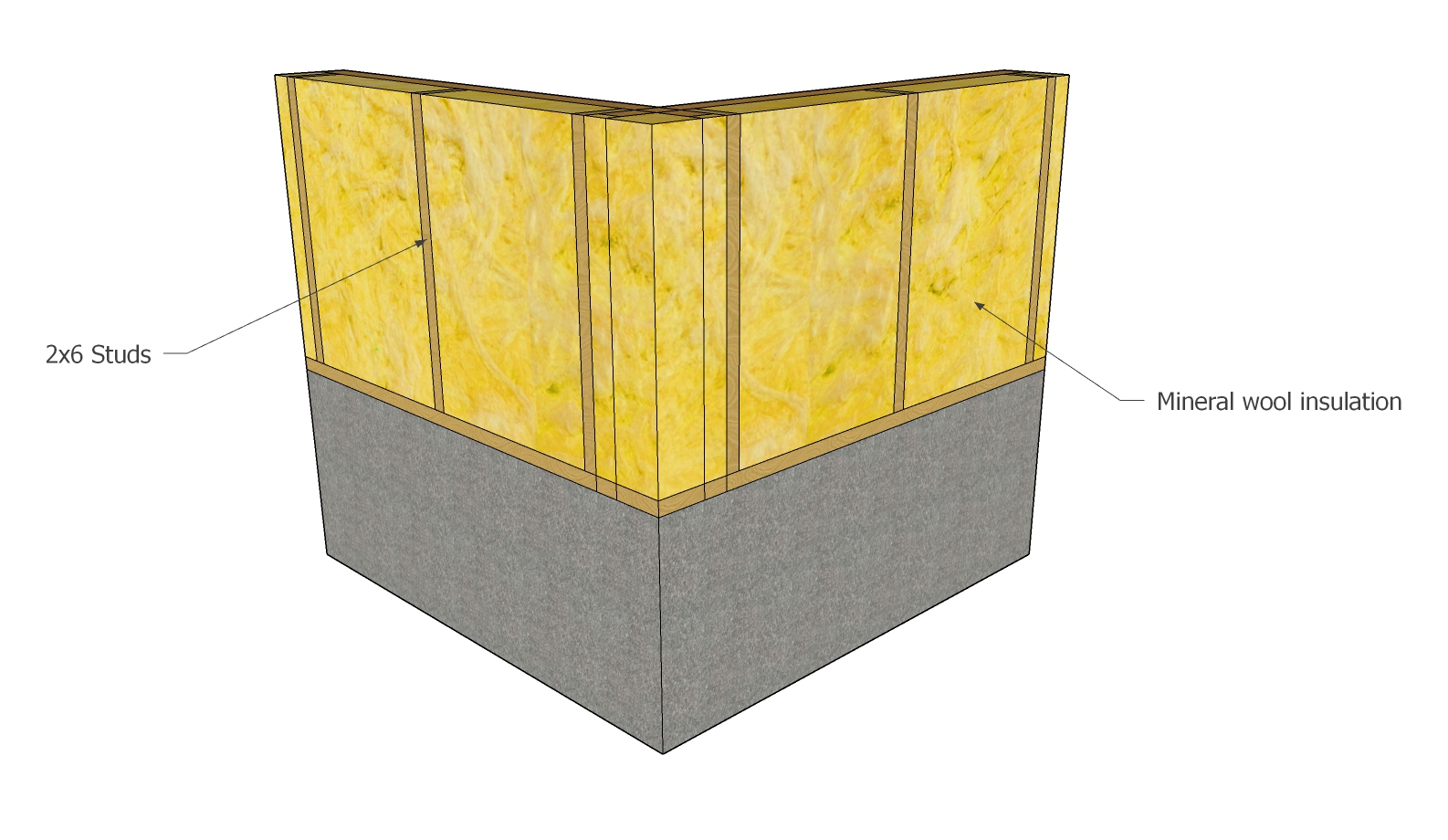

Our optional insulating/siding kits come with 2×6 studs spaced for 24″ on center. This allows for more insulation to increase total R-values. Any insulation can be used, fiberglass, mineral wool, rigid board insulation or spray foam. Vapor barriers and house wraps may be required based on the local building codes.

Mineral wool insulation is recommended for its superior qualities. It’s impervious to moisture with a higher R-value per inch than fiberglass, reduces noise levels & is environmentally friendly

(WALL LOG) R 4.4 + (INSULATION) R 23 = R 27.4

INSULATING ROOFS

Rafters are applied to the exterior, over the tongue & groove roof boards. The build up depth is determined by the R-value required to meet local building codes and the type of insulation used. High density spray foam provides the highest R-value for thickness & is water proof. Rigid, mineral wool or fiberglass insulation can be used

ENGINEERING DRAWINGS